Equipment Builds

Seeing a project through from start to finish is extremely important to us. We take pride in the fact that we can take your project needs, machine and fabricate your custom parts, purchase off the shelf commercial items, assemble the components, and deliver you a finished product that fills the need of your organization.

Whether your project needs Build to Print services or full engineering support, we have the staff to help make your project a success.

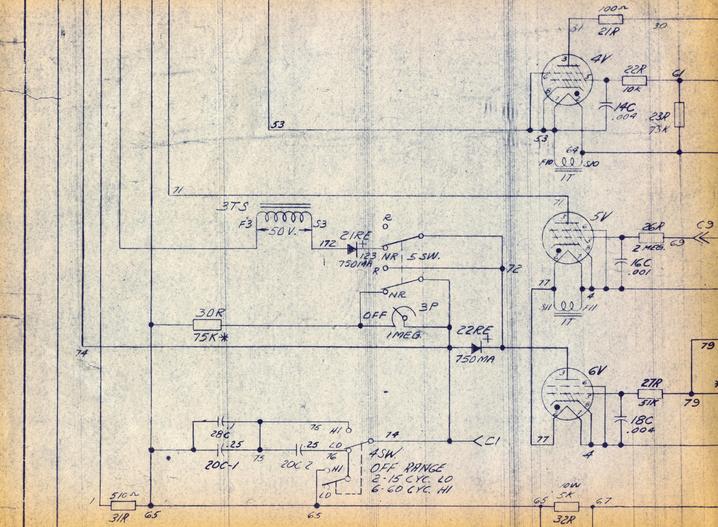

Electrical Assembly

Electrical assembly is a key component in building automated equipment and fixturing.

Mechanical Assembly

We have the staff that has the experience and background in multiple areas of assembly.

Protofab Engineering Qualifications

ISO 9001:2015 certified

DDTC Registered

ITAR Compliant

JCP Registered

Sam.gov Registered